How deep can a 20W fiber laser engrave

The laser beam is then amplified using an optical fiber and fed to a cutting head.

You can use 100% of the laser power to engrave stainless steel with a 30W fiber laser at a 90deg angle.

A 30W fiber Laser can engrave on stainless Steel at a 90deg angle, with a speedy speed 3,543 ipm.

It means that when working with metals that reflect laser beams they absorb fiber laser light much faster than the CO2 laser light.

High-concentrated power lenses with a longer focal length are used to expand the engraving area.

Once you access control to the machine through RetinaEngrave v3.0, you can start your first job. You can do all this in about 30 minutes.

The laser beam is then amplified using an optical fiber and fed to a cutting head.

You can use 100% of the laser power to engrave stainless steel with a 30W fiber laser at a 90deg angle.

All kinds of materials can be cut with laser machines. It is dependent on which type of laser machine your have that will allow you to cut different materials. Laser machines that use CO2 can't cut through reflective metallic materials such as brass, copper and aluminum. However, they are capable of cutting through nonmetallic materials like plastic and wood.

It is important to remember that a fiber laser has limitations in terms of both the size of your work-bed and the material you can cut.

FSL Muse Pandora has a mirror galvanometer in its laser head which traces out the laser path before cutting and gives a rough idea of the cuts it will make.

You should be aware that the fiber laser will have limitations on the size of your work area and the materials you can cut.

Fiber lasers shine in engraving applications. It can mark and etch metals with incredible speed.

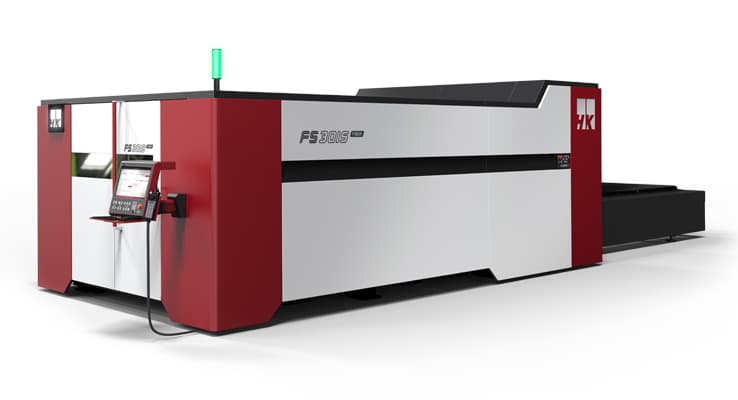

Our machines can cut steel, brass and aluminum without any back reflections. These fiber laser machines can reduce maintenance and operating costs.

Laser machines can be used to cut almost any type of material. The kind of laser machine used will affect the materials you can cut. However, a CO2 laser can cut through metals like copper, aluminum, and brass. They can however cut through nonmetallic substances like wood or plastic.

And we�ve been improving the technology�making it do more with fewer resources, making it easier for operators to use, and much more�ever since.

The wavelength is the primary distinction that determines the types of materials that each laser can process. The wavelength of a fiber laser is typically 1,060 nm, whereas CO2 lasers have wavelengths in the 10,600 nm range. Fiber lasers have many advantages over CO2 lasers in general.

Applications for the 50 Watt Fiber Laser Deep Engraving Machine:

Thin metals such as stainless steel, aluminum, alloy, brass, silver, gold, and titanium can also be cut by the deep laser engraving machine.

Compressed air, nitrogen, oxygen, and argon are the four primary types of assist gas for fiber laser machines.